Industry...

What Is Ready Mix?

Concrete is made up of three basic components. water, aggregate, and the cement that act as a binding agent when mixed with water and aggregates.

What are the Ready-mix

Uses?

Concrete is the most used construction material on the planet. It can be formed into various shapes when freshly mixed and hardened into a strong substance

How do we mix the Concrete?

There are so many methods of mixing ingredients of concrete. ALMISNED READYMIX Company has a good outlook and a high-efficiency Batching Plant. Our Batching plant is equipped with a fully automatic and computerized control system for mixing the ingredients.

How do we evaluate concrete?

Our experienced materials engineer works in our well-equipped Laboratory, supported by experienced Technicians to control the quality of concrete. We follow the ASTM, BS, AND QCS standards to monitor the quality of the ingredients used in the concrete. And, test the hardened concrete with a compression machine to evaluate the Strength of the supplied concrete.

What are the batching methods?

Batching can be done in 2 different ways:

Volume Batching:

In volume batching, each material is measured by a specifically fabricated volume scale.

Weight batching:

In weight batching, each material is measured with a weighing scale. The scale is monitored by a computer and has maximum tolerance factor of 0.03%.

Concrete casting process

After the concrete batching, the truck mixer will come to the checkpoint where the visual check will be carried out. After This process, the slump test will be done which will show the water-to-cement ratio for the concrete.

Troubleshooting

Common Problem | Causes | Action | Solution |

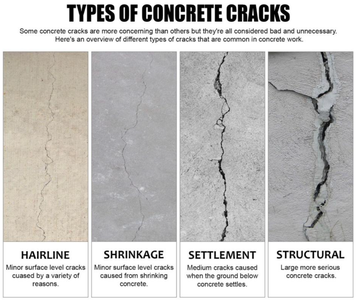

Concrete Cracks

| Cracking is one of

the most common forms of concrete damage. Cracks can be caused by factors such

as drying shrinkage, temperature changes, improper curing, and excessive loads.

Different types of cracks include hairline cracks, surface cracks, and deep

cracks.

|

| 1. Sealing and filling2. Routing and sealing3. concrete patching4. Overlay or Resurfacing |

Honeycombing

| Concrete honeycombing

refers to a condition in which voids or air pockets are present in the concrete

mix, often resembling a honeycomb pattern. This issue can weaken the structural

integrity and durability of concrete.

| 1. Construction site visiting2. Inspect the structure3. Datamine the root cause4. Make an analysis

5. Recommendation and proposal for repairing

| 1. Repair Mortar2. Grout Injection3. Surface Patching

4. Chipping and Re-pouring

|

Spalling

| occurs when the

surface layer of concrete flakes off, exposing the aggregate underneath. This

can be caused by freeze-thaw cycles, corrosion of embedded reinforcement, or

chemical reactions that cause the concrete to deteriorate.

|

| 1. Surface Patching2. Resurfacing3. Repair Mortar4. Epoxy Coating

5. Sealing and Waterproofing

|

Scalling

| Scaling is similar to

spalling but involves the loss of thin layers from the surface of the concrete.

It often occurs due to freeze-thaw cycles, where water penetrates the concrete,

freezes, and causes the surface to break off.

| 1. Construction site visiting2. Inspect the structure3. Datamine the root cause4. Make an analysis5. Recommendation and proposal for repairing. | 1. Surface Cleaning2. Surface Patching3. Resurfacing4. Proper Curing5. Sealing and Waterproofing |