5 Major Impact of Hot Weather Concreting

1. Rapid Water Loss

High temperatures can lead to increased evaporation rates, causing water to evaporate from the surface quickly, which can compromise the hydration process.

2. Accelerated Setting Time

Concrete may set faster in hot weather, reducing the working time available for finishing and increasing the risk of improper placement.

3. Increased Risk of Cracking

Rapid drying can lead to plastic shrinkage cracks, especially if the surface dries out before it has properly set.

4. Compromised Strength and Durability

If not properly managed, hot weather can lead to weaker concrete with reduced durability, impacting its long-term performance.

5. Inconsistent Quality

Variability in mix temperatures and conditions can lead to inconsistencies in the quality and performance of the concrete.

Best Practices for Hot Weather Concreting

To achieve successful hot weather concreting, it's essential to balance quality, costs, and resource availability. Although predicting weather and curing behavior can be challenging, consistently monitoring temperature and strength is crucial for effective curing. Here are key tips for each phase of the concrete process.

Planning

It is important to foreknow, plan, and coordinate in the initial phases of concrete manufacturing process for success under warm conditions. Begin by understanding the humidity levels on the project site while casting and curing the concrete. It is essential to reflect upon the ideal hours to pour the concrete, expected temperature, and whether it will be beneficial to pour and finish the concrete the same day considering the expected temperature.

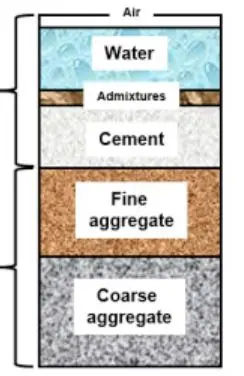

Batching and Mixing

After learning the anticipated weather conditions on site, the concrete mix design can assist in lowering the associated risk involved with hot weather concreting. Here are some of the aspects to take care of while batching and mixing.

- Reduce the cement content

- Add mineral admixtures

- Use Plasticizers

- Reduce concrete temperature

- Minimise transport time

Placing and Finishing

Warm weather can increase evaporation rates and reduce setting times, causing concrete to solidify quickly and become difficult to manage. As a result, the time available for placing, finishing, and curing concrete is shortened. To mitigate the effects of high temperatures on concrete strength, it’s advisable to schedule pours for late night or early morning, allowing for better curing conditions. Effective communication with the batching plant and subcontractors is also crucial.

Curing

The primary goal of the curing phase is to ensure that the cement hydration process maximizes the concrete mix's strength potential. To achieve this, it's essential to prevent moisture loss and avoid extreme temperatures.

The number of precautions to take depends on factors like construction type, ambient temperature, humidity, wind speed, and concrete temperature. A few or all of these measures may be implemented as needed.

Sufficient labour and placement equipment are crucial for quickly placing and finishing concrete. With proper precautions, the effects of hot weather can be effectively managed to ensure high-quality results.

REFERENCES

ASTM C94: Standard Specification for Ready-Mixed Concrete

ASTM C1074: Standard Practice for Measurement of Moisture in Freshly Mixed Concrete

ASTM C156: Standard Test Method for Water Retention of Hydraulic Cement-Based Materials

ASTM C1581: Standard Test Method for Determining the Cracking Tendency of Concrete

ASTM C1778: Standard Guide for the Selection of Admixtures for Concrete

ASTM C309: Standard Specification for Liquid Membrane-Forming Compounds for Curing Concrete

BS EN 206: Concrete – Specification, Performance, Production, and Conformity

EN 13791: Assessment of Concrete Compressive Strength by Non-Destructive Testing

BS EN 13670: Execution of Concrete Structures

BS EN 14845: Admixtures for Concrete

BS EN 12390: Testing Hardened Concrete

ACI 305R: Guide to Hot Weather Concreting

ACI 318: Building Code Requirements for Structural Concrete

ACI 211.1: Standard Practice for Selecting Proportions for Normal, Heavyweight, and Mass Concrete

ACI 232.2: Use of Fly Ash in Concrete

ACI 364: Guide for the Evaluation of Concrete

SECTION 5 PART 2: Aggregates

SECTION 5 PART 3: Cementitious Materials

SECTION 5 PART 4: Water

SECTION 5 PART 5: Admixtures

SECTION 5 PART 6: Property Requirements

SECTION 5 PART 7: Concrete Plants

SECTION 5 PART 8: Transportation and Placing of Concrete

SECTION 5 PART 10: Curing

SECTION 5 PART 14: Protective Treatments for Concrete

SECTION 5 PART 15: Hot weather concreting